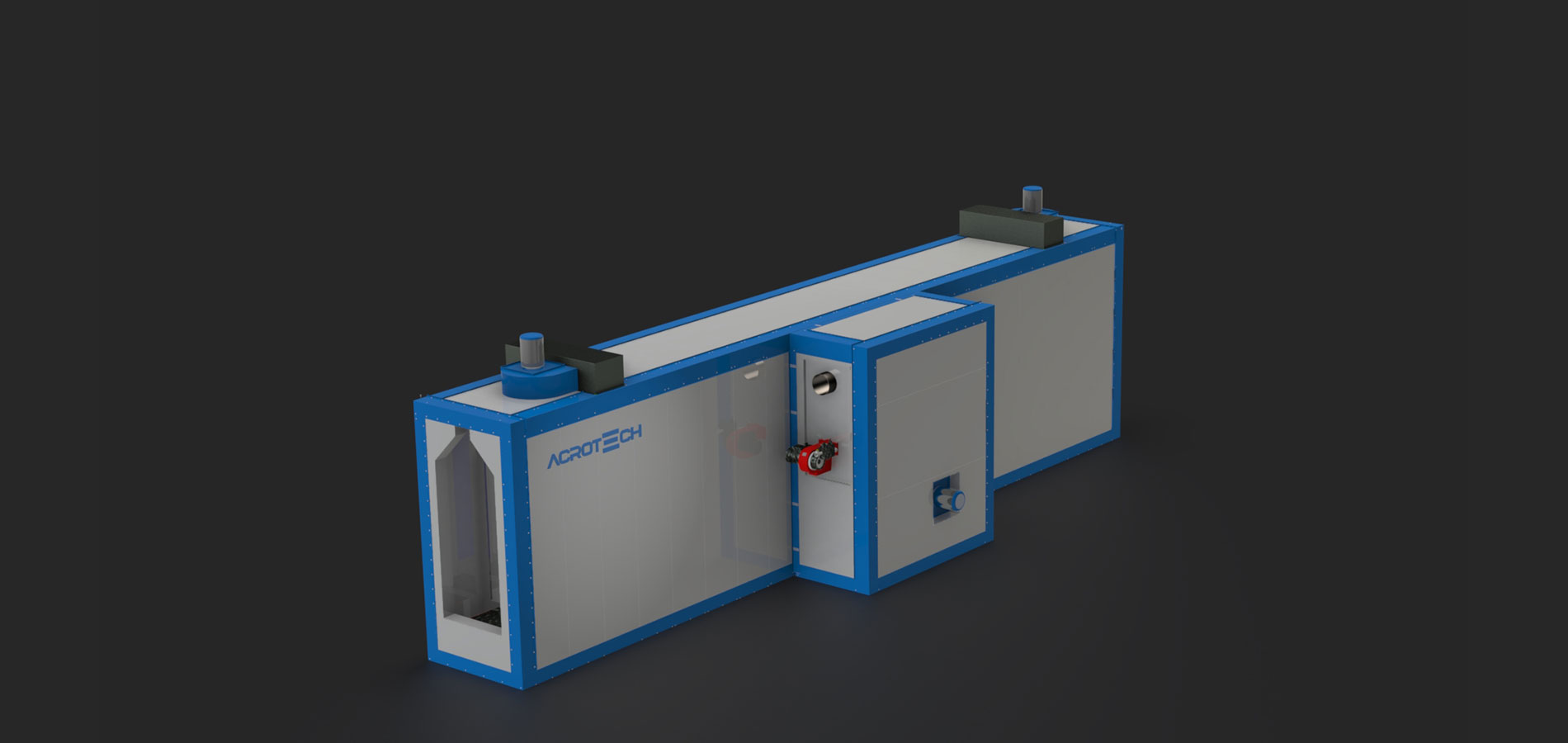

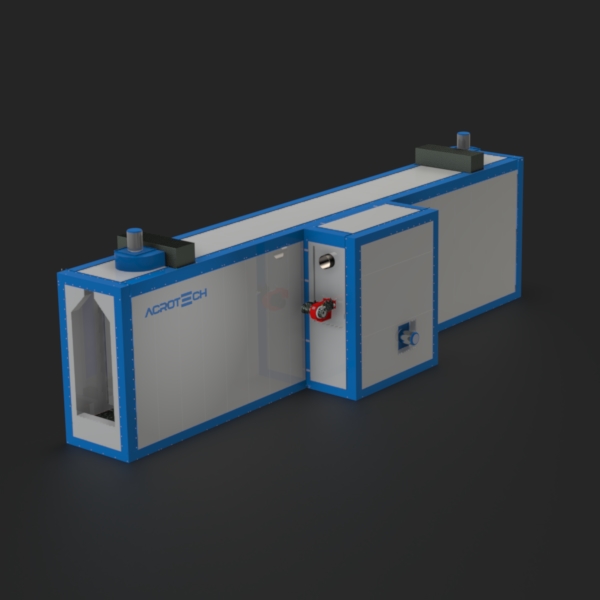

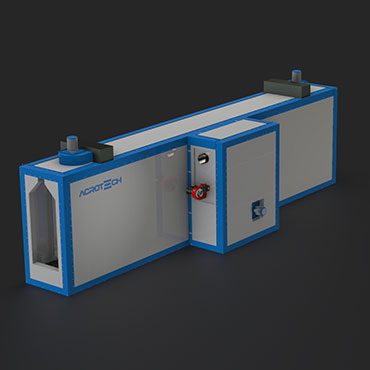

ACROTECH Tunnel Type cooking and drying ovens are manufactured in sandwich panels on the chassis and manufactured in de-assembled form. The inner part of the cooking oven is made of 1.2mm ST 37 Galvanized, the outer part of which is made of 1.2 mm ST 37 material. Oven outer sheet is coated with electrostatic powder paint and corrosion resistance is increased. Baking oven panels are isolated with 150mm insulation material as standard. The inner part of the oven panels is insulated with 50mm 53kg / m3 rock wool and the outer part with the 120mm glass wool, due to this insulation feature in the baking oven, the heat losses do not exceed the ambient temperature (+ - 10). In this way, our cooking ovens consume less fuel and do not heat the working environment more than necessary. There is a radiant type fan that provides air circulation in the cooking oven, and a homogeneous heat distribution is achieved in the oven thanks to the air ducts and channels located along the oven.

CONTACT

CONTACT